EPCON NEWS

3 Common Features of Custom Industrial Ovens

The number of industrial oven designs are almost as limitless as the number of industries and individual companies that use them. But there are some common features that you see used in customized industrial oven design:

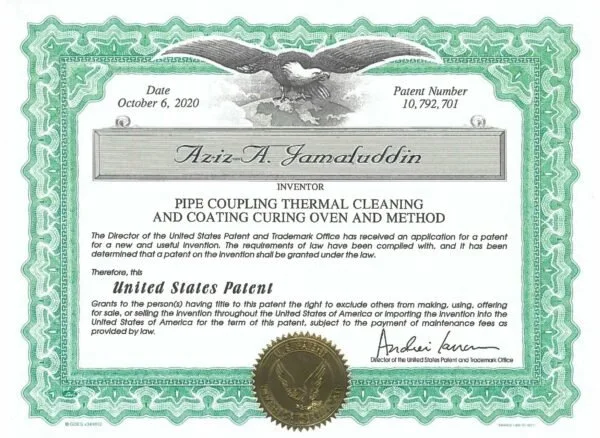

EPCON Awarded a New Patent

EPCON Awarded a New Patent One of Epcon’s advantages is building Ovens and Oxidizer combinations, and we recently were awarded a patent, # 10,487,283 for one shared Oxidizer for two Coil Coating Paint line Ovens, Prime and Finish.

Epcon – The Industry Leader

EPCON is a proud custom manufacturer, 100% Made in America, with quality products and attention to detail.

Season’s Greetings from Epcon

All of us at Epcon would like to wish you a Happy Holiday Season and Best Wishes for the New Year.

Please accept a heartfelt ‘Thank You’ for our continued success for over 40 years!

How Epcon’s Equipment Can Enhance Your Facility’s Finishing Systems

Epcon has been supporting finishing systems for facilities performing tasks such as cleaning (wash lines – multi-stage washers), painting and coating (paint booths) and curing (industrial ovens) for over 40 years.

Getting the Right Mix for a Thermal Catalytic Oxidizer

As you can see, adding a catalyst to a thermal oxidizer requires a lot of specialized knowledge and engineering skill to set up an effective thermal oxidizer system that destroys the VOCs and HAPs quickly, completely and at the lowest possible cost.

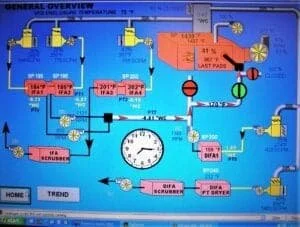

Regenerative Thermal Oxidizers (RTOs)

Used to destroy Volatile Organic Compounds (VOCs) such as hydrocarbons, solvents and other hazardous air pollutants, Regenerative Thermal Oxidizers are the most common air pollution control equipment in use today.

How does a Regenerative Thermal Oxidizer (RTO) Work?

What is happening inside the combustion chamber to break down the air pollution? This animation shows the various components and thermal mechanics of a RTO operation and demonstrates how the process air cycles through the system.

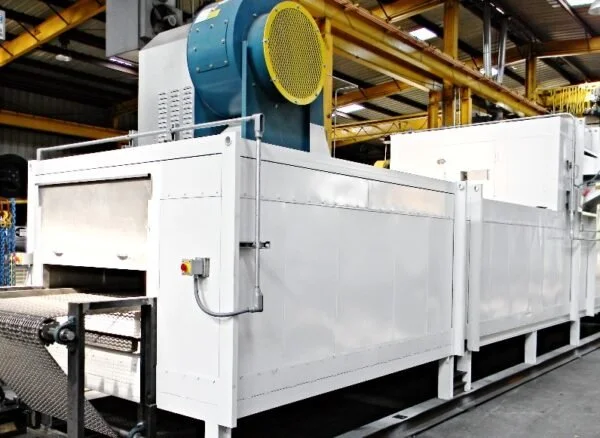

What is an Industrial Conveyor Oven and What is It Used For?

An industrial conveyor oven is an industrial batch oven that moves the product to be processed through it on a conveyor system.

High Volume Production

Demand for your product has grown so much that manufacturing your product one batch at a time is inefficient or is creating a bottleneck in the manufacturing process. It takes a lot of time to load, heat, cool and unload the product in a batch oven.

What are Batch Ovens and what are they used for?

This animation highlights the features of a 3–Compartment Gas Fired Aging Oven with Cooling Capacity. Batch Ovens are an ideal solution for aging, baking, curing, drying, finishing, heat treating, hardening, or pre-heating.

Get the Best in Industrial Conveyor Oven Design at Epcon Industrial

At Epcon, we have over 40 years of experience in industrial oven design. Reach out to one of our industrial oven design experts today by completing our simple online Get a Quote form, call us at (936) 273-3300, or send us an email at epcon@epconlp.com.

Air Flow Configuration

A critical component of a custom industrial oven is the duct work that controls the air flow through the process. Since the heat source for this process is delivered by forced air convection (most of the time), this has a significant impact on the overall industrial oven design.

Looking to Add a Catalyst to Your Thermal Oxidizer Setup?

Contact one of our thermal oxidizer engineering experts at (936) 273-3300, email us at epcon@epconlp.com, or complete our simple online contact form, to get the information you need.

Need More Information About Thermal Deoiler Systems?

Are you looking for a thermal deoiler system that will reduce your energy consumption and cost? Give us a call at (936) 273-3300, email us at epcon@epconlp.com, or complete our simple online contact form to reach out to one of our experts today.

Cure uniformity critical to laminated aluminium sheet performance

Increasing demand for affordable, lightweight, stamped metal parts has driven the development of specialty laminated metal products. These engineered materials combine the attributes of different gauges and grades of metal sheet, with those of high density polymer mastic dampening materials.

Epcon Delivers World-Class Custom Thermal Deoilers

We have been busy lately delivering custom industrial ovens, direct fired thermal oxidizers, but we’ve recently delivered several custom thermal deoilers based on our patented method of coupling heat processing systems and air pollution control systems to deliver these results.

Looking for Rental Thermal Oxidizers?

Then be sure to check out Epcon’s full range of rental regenerative and recuperative thermal oxidizers. All of them, including trailer-mounted oxidizers are fully inspected and backed by our tech support and available for immediate delivery.

Is Epcon working for you?

Epcon is a full-service organization, from concept to completion; we can help you achieve your goals of either new equipment or modernizing your existing equipment for higher fuel efficiency, better performance, and compliance with the regulatory agencies.