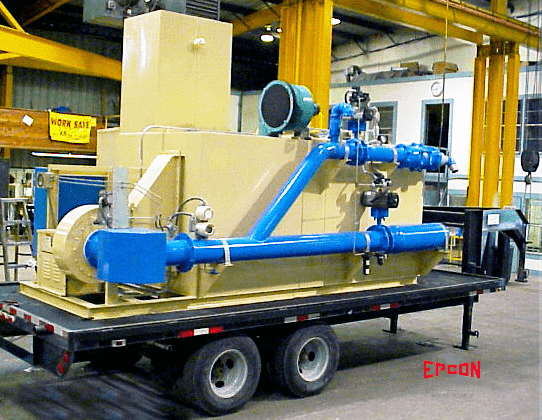

Trailer Mounted DTFO Unit for Soil Remediation by US Military

The Challenge

The US Military needed a system for remediation work at their bases. The objective was to safely destroy highly-poisonous gasses emitted from dismantling weapons, bombs, hand grenades, and other munitions. The system needed to operates on Propane and be transported easily from location to location, as needed.

The Solution

After extensive evaluation and consideration of the existing system operation, it was determined that the optimal solution for this application is the use of a combination system layout, consisting of a 3-Zone Prime Oven & 4-Zone Finish Oven with a single standalone Thermal Oxidizer system, along with the secondary heat recovery system. The combination system works to capitalize on every part of the process, ensuring no heat nor material go to waste.

With Coil Coating Ovens, it is common to design the Oven with multiple zones, depending on the process. The different zones within the Oven allow for a gradual heating process, which can be a vital component when dealing with certain materials, such as paint or metal. In this particular system, the 3-Zone Prime Oven cures the primer onto the metal as the metal is processed through the Oven, reaching temperatures between 500-600°F. The 4-Zone Finish Oven continues to cure the paint onto the metal as the metal passes through each zone, gradually achieving the desired, peak metal temperature.

As the painted metal strips are being cured through the Prime & Finish ovens, the paint solvents evaporate into the Oven’s work chamber. The air laden with VOCs, is extracted from the Oven’s work chamber and routed through the Primary Heat Exchanger of the Thermal Oxidizer. The Primary Heat Exchanger pre-heats the Oven exhaust in excess of 1100 °F temperature to minimize the Oxidizer’s burner fuel consumption. The VOC exothermic reaction contributes in making the Oxidizer’s retention chamber act as a self-sustaining agent without any additional burner heat input.

The use of a Secondary Heat Exchanger further establishes an efficient, economic solution. Once the contaminated air in the Prime & Finish Coater room is effectively captured by the Thermal Oxidizer, it is routed through the Secondary Heat Exchanger. The Secondary Heat Exchanger continues to supply the pre-heated air back to both the Prime & Finish Ovens, thus increasing sustainability.

As demonstrated by this metal coating operation, by continuously recycling the heat between the Oxidizer and Ovens via two Heat Exchangers, the combination system creates optimal operational efficiency and allows the facility to capitalize on the thermal energy across the entire process.

The Results

The mobile unit not only gives the facility the flexibility they need, but the self contained propane driven unit is also convenient and simple to use.

The DTFO’s allow the for the safe destruction of all VOCs and HAPs in the remediation process.